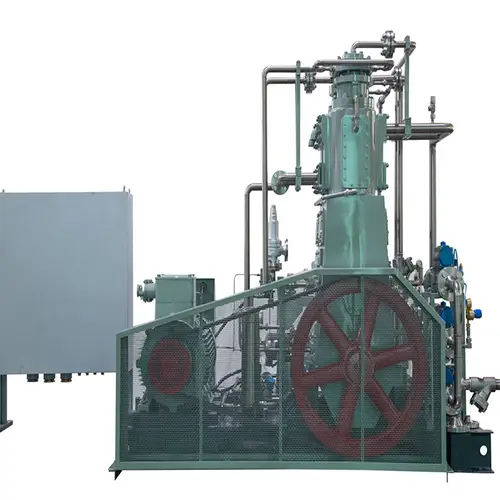

China Factory OW-20/4-150 Totally Oil-Free Oxygen Compressor (20Nm3/h, 150bar) with Hot Selling

The China Factory OW-20/4-150 Totally Oil-Free Oxygen Compressor is a high-quality and efficient compressor designed for various industrial applications. It is specially designed to provide oil-free and contaminant-free oxygen, ensuring the purity and reliability of the compressed gas.

Product Description

The OW-20/4-150 compressor is a part of our Oil-Free Booster Compressor series. With its advanced technology and superior performance, it is highly suitable for applications that require high-pressure oil-free compressed oxygen gas. The compressor operates at an inlet pressure of 0.4Mpa(G) and delivers an exhaust pressure of 150/200Mpa(G).

Features:

- Oil-Free Booster Compressor

- Model No: BW-3/5/10/15/20/30…

- Type: High Pressure Oil Free

- Accessories: Filling Manifold, Piston ring, etc.

Oilless High Pressure O2 Compressor Specification:

| NO | Volume | Inlet pressure | Outlet pressure | Type | Cooling type |

|---|---|---|---|---|---|

| 1 | 1-3m³ | 0.3-0.4MPa | 15MPa | 2 lines 4 stages vertical type | Wind |

| 2 | 4-12m³ | 0.3-0.4MPa | 15MPa | 2 lines 4 stages vertical type | Wind |

| 3 | 13-40m³ | 0.3-0.4MPa | 15MPa | 3 lines 3 stages W type | Water |

| 4 | 13-60m³ | 0.2-0.4MPa | 15MPa | 2 lines 4 stages vertical type | Water |

| 5 | 40-80m³ | 0.2-0.4MPa | 15MPa | 4 lines 4 stages S type | Water |

| 6 | 80-120m³ | 0.2-0.4MPa | 15MPa | 4 lines 4 stages S type | Water |

If you have a compressor inquiry, please provide the following information:

- Compressor working medium: If single gas, how many purity? If mixed gas, what’s the gas content lit?

- Suction pressure(gauge pressure): _____bar

- Exhaust pressure(gauge pressure): _____bar

- Flow rate per hour for compressor: _____Nm³/h

- Compressor gas suction temperature: _____ºC

- Compressor working hours per day: _____hours

- Compressor working site altitude: _____m

- Environment temperature: _____ºC

- Has cooling water in the site or not? ______

- Voltage and frequency for 3 phase: ____________

- Does the gas contain water vapor or H2S? ______

- Application for compressor? ____________

Other Products by EVER-POWER GROUP

EVER-POWER GROUP is a leading supplier of various industrial products. In addition to the China Factory OW-20/4-150 Totally Oil-Free Oxygen Compressor, we offer a wide range of products for industrial use. Our product range includes agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing high-quality products, competitive prices, and excellent customer service.

Customers are welcome to customize drawings and samples according to their specific requirements. If you are looking for reliable and durable industrial products, look no further than EVER-POWER GROUP.

Frequently Asked Questions (FAQs)

Q1: Are your products original spare parts?

A1: No, our products are replacement parts rather than original spare parts.

Q2: Do your replacement parts fit perfectly with the original spare parts?

A2: Yes, our replacement parts are designed to perfectly fit the original spare parts.

Q3: How can I purchase original spare parts?

A3: If you need to purchase original spare parts, please contact the original factory or supplier.

Q4: Is all the content on the page from the internet?

A4: Yes, all the content on the page is used as a reference for product selection.

Q5: Can I customize my order?

A5: Yes, we welcome customers to customize their orders according to their specific requirements.

All content on the page comes from the Internet. The content is only used as a reference for product selection. Our products are replacement parts rather than original spare parts; we are not the holders of the original trademark of the content, and our products are only suitable for after-sales replacement parts, not original spare parts. Our replacement parts can perfectly fit the original spare parts; if you need to purchase original spare parts, please contact the original factory or supplier.

Performance Characteristics of Oxygen Compressors

1. High Compression Efficiency

Oxygen compressors are designed to efficiently compress oxygen gas, ensuring maximum output and performance. The compression process is carefully engineered to minimize energy consumption while maintaining high compression ratios.

2. Reliable Operation

These compressors are built to provide dependable and consistent operation. By utilizing advanced technology and robust construction, they offer reliable performance even in demanding environments. This ensures continuous and uninterrupted oxygen supply.

3. Compact and Space-Saving

Oxygen compressors are designed to be compact and space-saving. Their small footprint allows for easy installation in various settings, making them suitable for both small-scale and large-scale applications.

4. Low Noise and Vibration

Efforts have been made to reduce noise and vibration during the operation of oxygen compressors. By incorporating soundproofing materials and effective vibration dampening systems, they provide a quieter and more comfortable working environment.

5. Precise Control and Monitoring

Modern oxygen compressors are equipped with advanced control and monitoring systems. These enable precise adjustment of compression parameters and real-time monitoring of key performance indicators, ensuring optimal operation and efficiency.

Types and Characteristics of Oxygen Compressors

1. Piston Compressors

Piston compressors utilize reciprocating motion to compress oxygen gas. They are known for their high compression ratios and are suitable for applications requiring higher pressure output. These compressors can handle a wide range of oxygen flow rates and are often used in industrial and medical settings.

2. Rotary Screw Compressors

Rotary screw compressors use a pair of intermeshing screws to compress oxygen gas. They offer a continuous and smooth operation, making them ideal for applications requiring a constant supply of compressed oxygen. These compressors are widely used in industries such as oxygen generation systems and environmental applications.

3. Scroll Compressors

Scroll compressors utilize two spiral-shaped scrolls to compress oxygen gas. They are compact, lightweight, and known for their quiet operation. These compressors are commonly used in portable oxygen concentrators and medical devices due to their efficiency and reliability.

Advantages of Oxygen Compressors Made of Different Materials

1. Aluminum Alloy

Oxygen compressors made of aluminum alloy offer excellent corrosion resistance and lightweight properties. They are suitable for portable and mobile applications, providing convenience and ease of transportation.

2. Stainless Steel

Oxygen compressors constructed with stainless steel provide superior durability and resistance to harsh environments. They are commonly used in industrial applications where corrosion resistance and longevity are essential.

3. Titanium Alloy

Titanium alloy oxygen compressors are highly regarded for their exceptional strength, low weight, and excellent corrosion resistance. They are often utilized in aerospace and medical industries where high performance and reliability are crucial.

Application of Oxygen Compressors

Oxygen compressors find valuable applications in various fields, including:

Oxygen Therapy

Oxygen compressors play a vital role in delivering concentrated oxygen to patients for therapeutic purposes. They ensure a steady supply of oxygen for individuals with respiratory conditions, promoting better health and well-being.

Oxygen Generation Systems

These compressors are integral components of oxygen generation systems, which produce oxygen from ambient air. They enable the efficient compression of oxygen gas, allowing for its storage and distribution to meet diverse industrial needs.

Medical Applications

In medical settings, oxygen compressors are used for various applications, such as anesthesia, respiratory support, and surgical procedures. Their reliability and performance are essential for maintaining patient safety and providing precise oxygen delivery.

Industrial Applications

Industries utilize oxygen compressors for applications like metal cutting, welding, and chemical processing. The compressors ensure a constant and reliable supply of compressed oxygen, enhancing productivity and efficiency.

Environmental Applications

Oxygen compressors are employed in environmental applications such as water treatment and waste management. They facilitate processes that require the use of oxygen, contributing to effective and sustainable environmental practices.

Safety-Related Purposes

Oxygen compressors are critical for safety-related purposes, including firefighting, emergency response, and hazardous gas detection and control. They provide the necessary oxygen supply for ensuring the safety and well-being of individuals in critical situations.

Future Development Trends and Opportunities

The future of oxygen compressor products holds exciting prospects for innovation and advancement. Some key trends and opportunities include:

1. Enhanced Energy Efficiency

Continued research and development efforts aim to improve the energy efficiency of oxygen compressors. This will help reduce energy consumption, operating costs, and environmental impact.

2. Integration of IoT Technology

The integration of Internet of Things (IoT) technology can enable remote monitoring and control of oxygen compressor systems. This connectivity enhances efficiency, predictive maintenance, and performance optimization.

3. Focus on Sustainable Solutions

The industry is shifting towards more sustainable solutions, including the use of renewable energy sources and eco-friendly materials. This focus on sustainability presents opportunities for the development of greener oxygen compressor technologies.

Choosing a Suitable Oxygen Compressor

When selecting an oxygen compressor, consider the following aspects:

1. Clear Requirements

Clearly define your specific requirements, including the desired oxygen flow rate, pressure levels, and application needs. This will help you choose a compressor that meets your specific demands.

2. Material Selection

Evaluate the materials used in the construction of the compressor. Consider factors such as corrosion resistance, durability, and suitability for the intended environment.

3. Design Optimization

Optimized compressor designs can offer improved efficiency, reduced noise, and better performance. Consider compressors with advanced design features that align with your requirements.

4. Suppliers and After-Sales Service

Choose reputable suppliers who provide quality products and reliable after-sales service. This ensures timely support, maintenance, and spare parts availability.

5. Cost-Effectiveness and Quality Control

Evaluate the overall cost-effectiveness of the compressor, considering factors such as initial investment, operational costs, and maintenance requirements. Additionally, ensure that the compressor undergoes rigorous quality control measures to guarantee its performance and longevity.

Author: Dream